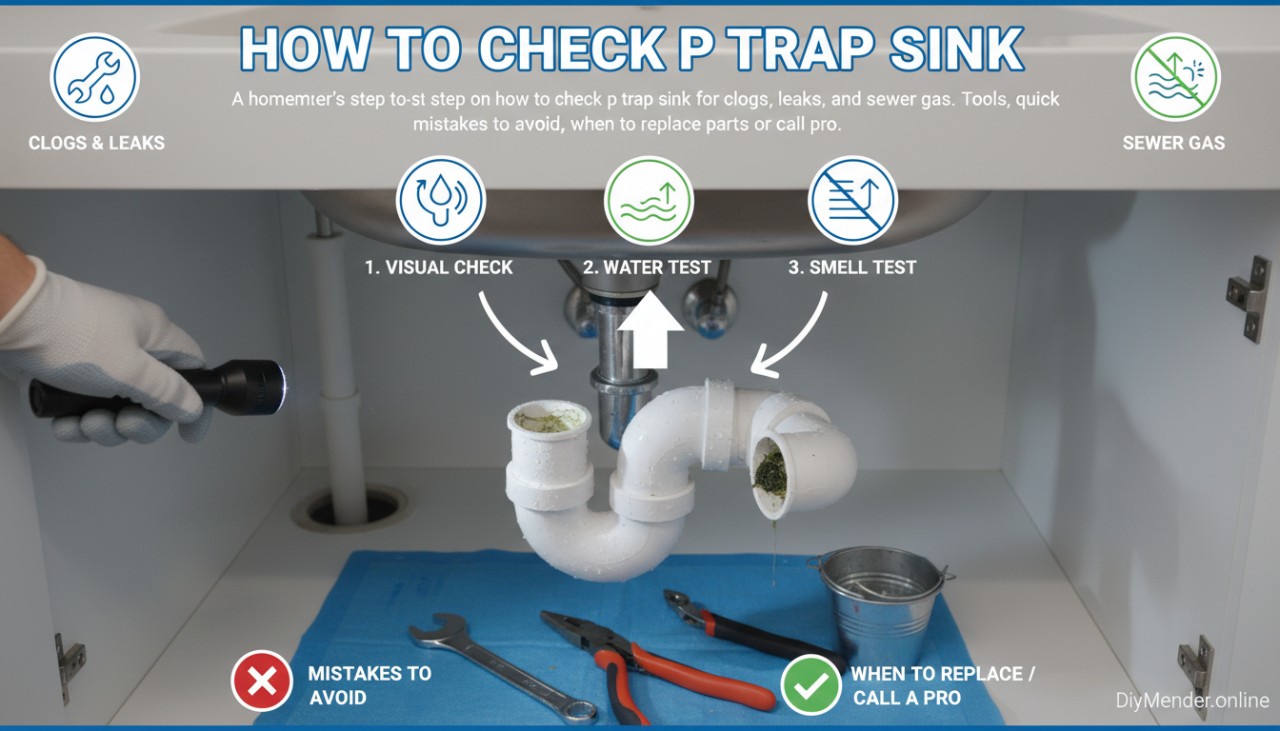

If you just want the short version for how to check p trap sink: run water, sniff for sewer gas, feel for leaks, and confirm the trap holds a small water seal. If flow is slow or there is smell, remove the trap, clear the gunk, replace the washers, and reassemble without over-tightening. That sequence catches 90 percent of issues in under 20 minutes.

I am a hands-on homeowner and here is exactly how I check a sink P-trap and why each step works.

What you need

Bucket or pan, old towel, rubber gloves

Adjustable pliers or channel locks

Flashlight, paper towels or tissue

Replacement slip-joint washers and a spare P-trap gasket

Zip tie or skewer as a dipstick, tape measure

Why the P-trap works (and why it fails)

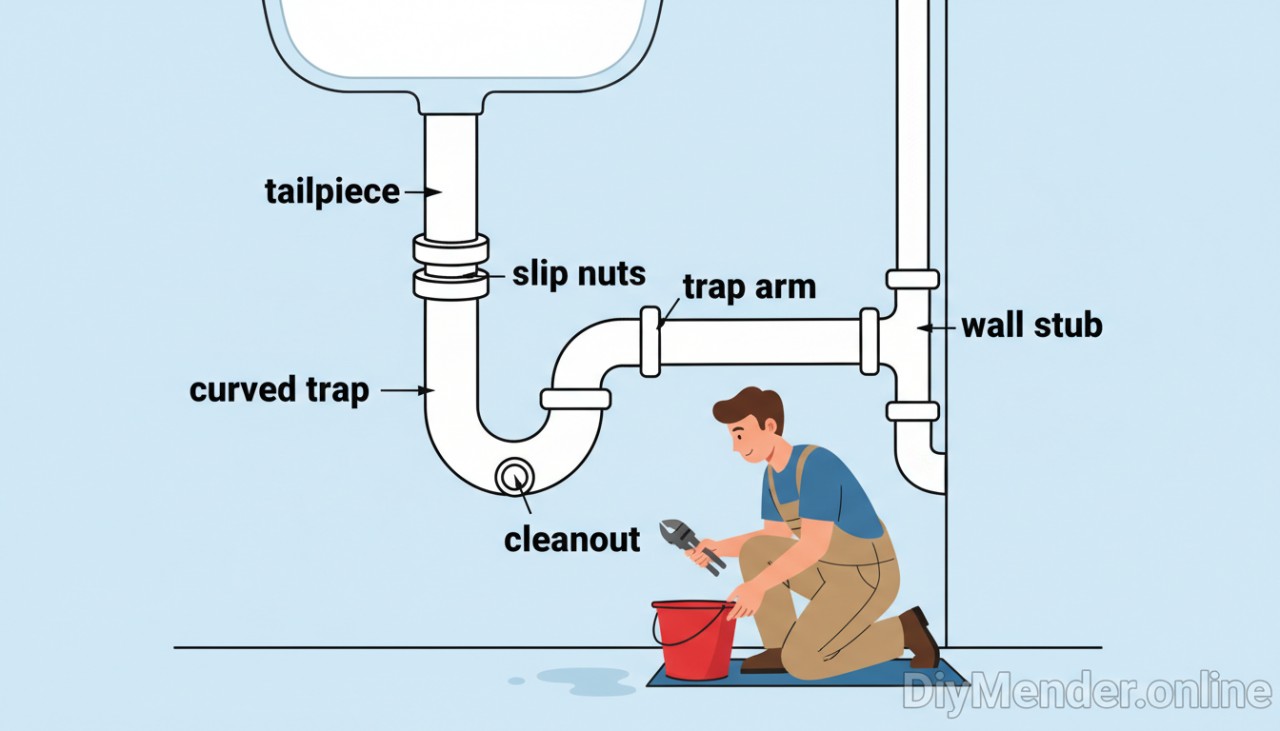

A P-trap is a U-shaped pipe that always holds a pool of water. That water is a seal that blocks sewer gas from drifting into the room. When it fails, it is usually one of three things: no water seal due to evaporation or a siphoning vent issue, a clog of hair or grease slowing drainage, or a leak from worn washers or overtightened misaligned nuts. Knowing that helps you test in a logical order.

Here is a quick diagram so you know what you are looking at under the sink. It shows the tailpiece from the drain, the curved trap, the trap arm into the wall, slip nuts, and washers.

My 5 minute checks before disassembly

1. Smell and seal

Sniff near the drain. Sewer smell with normal flow usually means the trap is dry. Run the faucet for 10 seconds and put the stopper in for a minute. If the smell vanishes, the issue was an evaporated seal from an infrequently used sink. That is normal; keep water in it by running weekly or add a teaspoon of mineral oil to slow evaporation. If smell returns after draining, suspect siphoning due to poor venting or an S-trap configuration that self-siphons.

2. Flow test

Fill the sink a few inches and pull the stopper. A healthy P-trap gulps smoothly with a stable water level in the bowl. If the water sits and swirls, you likely have a clog in the trap or the trap arm. If you hear gurgling, that is often a venting problem allowing the trap to empty itself and break the seal.

3. Quick leak check

Dry all joints with a paper towel, then run hot and cold for 30 seconds. Wipe the joints again. Any dampness around slip nuts or the cleanout plug points to a bad washer or loose connection. Leaks show up most during flow, when the trap is pressurized by the column of water in the sink.

4. Water seal depth

Shut the faucet. Slip a small zip tie down the drain until it bottoms in the trap and mark your finger location at the drain opening. Measure the wet portion. You want roughly 2 to 4 inches of seal. Less than 2 inches is vulnerable to evaporation and sewer gas; more than 4 inches can self-siphon. If the seal is off, the trap may be the wrong model or installed wrong.

5. Trap arm slope and alignment

The horizontal trap arm should pitch slightly downward to the wall, about a quarter inch per foot. If it sags or back-pitches, solids sit and rot, causing smell and clogs. If it is jammed upward, you may be forcing a misalignment that crushes the washer and leaks.

When to open the trap and how I do it

If you have slow drainage, obvious smell after refilling, or a leak, it is time to drop the trap. Put a bucket under it. Loosen the two slip nuts by hand first; use pliers only if needed. On plastic traps, I stop at snug-plus a quarter turn. On chrome brass, I protect the nut with a cloth to avoid bite marks.

Remove the U-shaped trap. Dump the goop into the bucket and clean it thoroughly. Hair, biofilm, coffee grounds, and hardened grease are common culprits.

Check the washers. The beveled side must face into the nut toward the mating flare. Flattened, cracked, or flipped washers leak.

Peek into the trap arm toward the wall. If it is packed, use a plastic drain brush or hand auger. Avoid chemical drain cleaners; they can damage finishes and do not remove solids effectively.

Reassemble dry-fit first to ensure alignment. The trap should slide on easily without forcing. Tighten by hand until snug, then a gentle tweak with pliers if needed.

Test: Fill the sink full and drain while watching every joint. Wipe with a dry tissue to catch weeps. No drips, no smell, smooth flow means you are done.

Common mistakes I see

Overtightening slip nuts. This crushes plastic washers and deforms metal traps, causing leaks.

Wrong washer orientation. The bevel must seat into the flare. Backwards washers leak every time.

Using flexible accordion traps. They trap debris and break the water seal easily. Replace with smooth-wall traps.

Double trapping. If a disposal or bottle trap adds another water seal in series, you get slow drains and siphoning.

Ignoring venting. Persistent gurgling and recurring dry traps point to a vent issue; a P-trap cannot fix that by itself.

Edge cases and limits

Garbage disposal: Check the dishwasher knockout on the disposal body is opened if a dishwasher is connected. A plugged knockout masquerades as a clog. Also clear the disposal before blaming the trap.

Pedestal or tight vanities: Remove the pedestal cover or the back panel for access rather than muscling the trap at an angle.

Metal traps: If chrome brass is pitted or seized, replace it. Mixed metal to plastic transitions benefit from new washers and a bit of plumber’s grease on threads.

S-traps: If your under-sink drain drops straight into the floor without a horizontal trap arm to a vent, it is an S-trap. These self-siphon by design and are often not code-compliant. You will chase smells until it is re-piped with a proper vented P-trap.

Rare sewer gas despite a good seal: Look for a cracked wall arm, a hidden cleanout without a cap, or a leaky gasket at the sink’s basket strainer. Not every smell is the trap.

When to replace vs repair

Replace the trap if it is corroded, cross-threaded, badly misaligned, or if you have repeated leaks despite new washers. P-trap kits are inexpensive and faster to install than fighting worn parts. Make sure you match the size, typically 1 1/4 inch for bathroom sinks and 1 1/2 inch for kitchens.

When to call a pro

If you have recurring gurgling or dry traps, you likely have a venting or slope issue in the wall. If the trap arm disappears into a stud bay with no accessible cleanout and snaking fails, a plumber with a camera will save you time. For everything else, a bucket, new washers, and methodical checks usually restore a perfect, odor-free P-trap.