If water is pooling in the cabinet, don’t panic. Most under-sink leaks come from a few simple spots and can be fixed with basic parts. Here’s how to repair a leaking pipe under the sink the same way I handle it at home: find the source, stop the drip, then make a durable repair instead of a band-aid.

Find Exactly Where the Water Starts

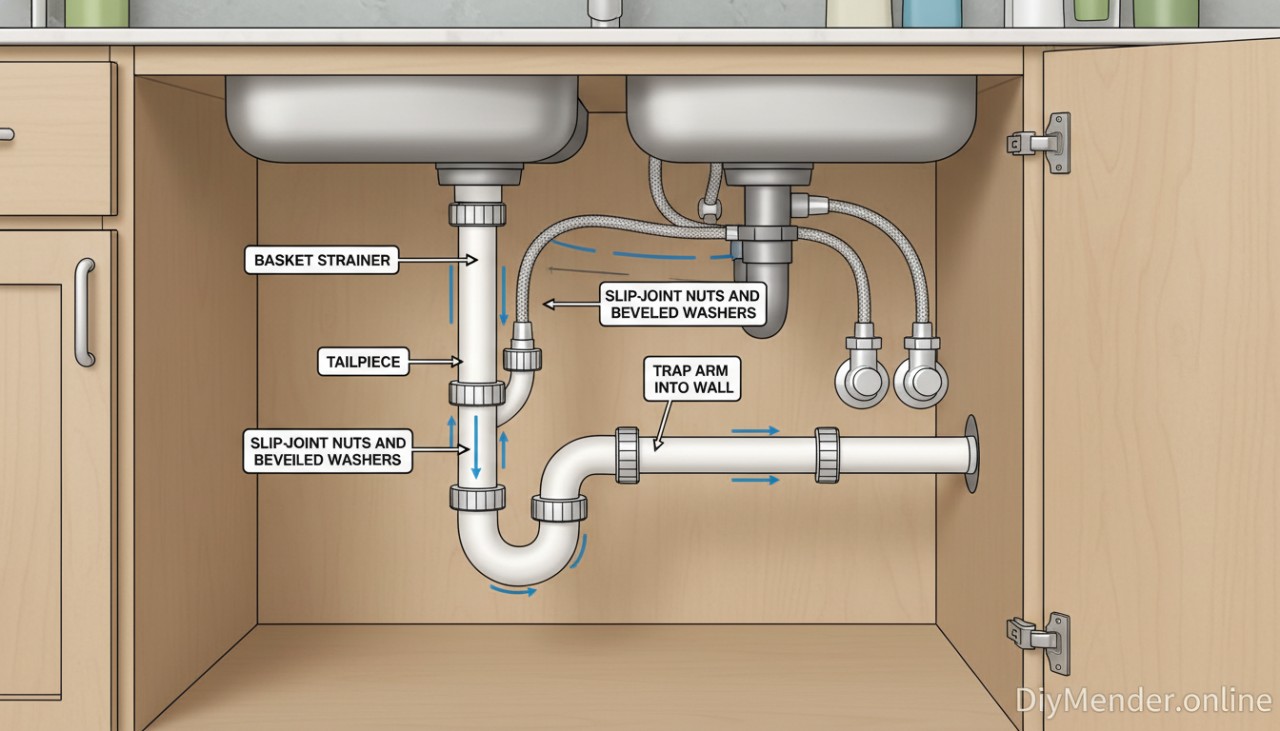

Dry everything first. Wipe the P-trap, tailpiece, basket strainer underside, supply lines, and shutoff valves. Then place a dry paper towel under each suspect joint and run water. Leaks usually show up at slip-joint nuts (on the drain), the faucet supply hoses, or the valve stems where the handle meets the shutoff.

Watch for these patterns: a drip only when the sink drains points to the P-trap, tailpiece, or basket strainer. Constant dampness even with the faucet off usually means a supply line or shutoff valve. Splashing only during vigorous use can be a loose tailpiece or misaligned trap.

How to Repair a Leaking Pipe Under the Sink: Step by Step

Before you start, clear the cabinet, place a bucket and towels inside, and have a flashlight. Turn off the shutoff valves if you’ll touch any supply lines, and open the faucet to relieve pressure.

1) Fix Common Drain (P-Trap) Leaks

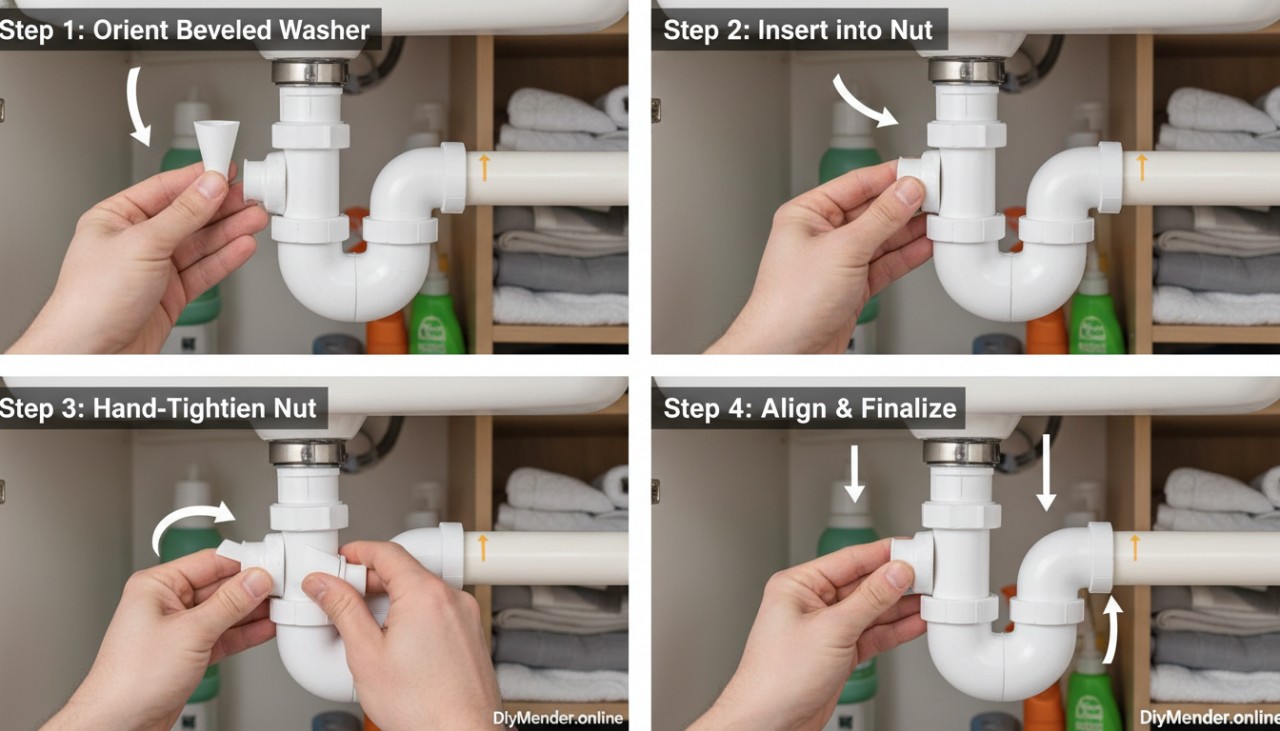

Most drain leaks come from misaligned pipes or tired slip-joint washers. On plastic drains, the beveled washer must face the joint, with the fat end toward the nut. Hand-tighten first, then give the nut a gentle additional quarter-turn. Overtightening deforms washers and causes persistent drips.

- If a nut won’t catch, back it off and realign the pieces; cross-threading is common in tight cabinets.

- Replace any flattened or cracked washers. Keep a mixed pack of 1-1/2 in. and 1-1/4 in. slip-joint washers; bathroom sinks are often 1-1/4 in., kitchens 1-1/2 in.

- If the trap arm is cocked or under stress, add a short extension or adjustable trap to relieve strain. Forced angles always leak later.

Metal traps corrode and pit over time. If you see pinholes, green crust, or rough threads, replace the trap assembly with PVC or new chrome. Trying to seal corrosion with tape rarely lasts.

2) Tailpiece and Basket Strainer Issues

If water appears at the tailpiece right under the drain, the slip-joint washer might be upside down or missing. Reinstall with the bevel toward the flared joint and tighten evenly. If the leak starts higher at the sink drain itself, the basket strainer putty or rubber gasket is failing.

- To reset a basket strainer, disconnect the tailpiece, remove the strainer locknut from below, lift out the strainer, clean all old putty, then bed it with fresh plumber’s putty or the gasket supplied by the manufacturer. Tighten the locknut firmly while keeping the strainer centered.

- Do not use silicone if you plan to service it later; putty remains workable and seals well on stainless sinks.

3) Supply Line and Shutoff Valve Leaks

Drips on braided lines are a replace-not-repair situation. Shut off water at the main if the local valve won’t stop, then swap the hoses. Use new braided stainless lines of the correct lengths so there’s a gentle loop, not a tight bend. Snug the connections—compression side at the valve and faucet threads hand-tight plus a small turn. Over-torquing deforms ferrules and crushes soft seats.

- If the leak is at the valve stem (around the handle), snug the small packing nut a quarter turn. If it still weeps or the valve is frozen, replace the valve. Old multi-turn stops often fail; quarter-turn ball valves are a good upgrade.

- Use two wrenches when tightening at the valve: one to hold the valve body steady, one to turn the nut. Twisting the valve can crack old copper stubs inside the wall.

4) Pipe Thread vs. Compression: Sealants That Actually Work

Teflon tape or pipe dope belongs on tapered pipe threads (like some dishwasher elbows or threaded adapters), not on compression fittings or slip joints. Slip joints seal with their washers; adding tape prevents proper seating and causes leaks later.

5) Temporary Measures While You Wait for Parts

For a cracked plastic trap or a pinhole in thin metal, epoxy putty or self-fusing silicone tape can buy you a day or two. These are short-term measures only; water exposure and movement will break the seal. Replace the damaged section as soon as possible.

Why Leaks Start in the First Place

Under-sink drains get bumped by cleaning supplies, trash bins, and even door hinges. That movement loosens nuts and misaligns slip joints. Heat cycles from dishwashers and hot water relax plastic washers. On older metal traps, corrosion thins the wall until it weeps. Supply lines simply age out—rubber liners harden and fittings fatigue. Understanding these failure modes helps you choose a lasting fix instead of chasing the symptom.

Quick Diagnostic Shortcuts

- Leak only when draining: focus on P-trap, tailpiece, basket strainer.

- Leak only when running water: check faucet connections and tailpiece.

- Leak constantly, even off: check supply lines and shutoff valves.

- Mystery damp cabinet: run a dry tissue around every joint, starting high and moving down; water travels along pipes before it drips.

Parts and Tools I Keep on Hand

A small kit avoids late-night hardware runs: mixed slip-joint washers, a universal P-trap kit, two braided supply lines, plumber’s putty, Teflon tape, a small adjustable wrench, a tongue-and-groove plier, a flashlight, and a towel. With these, 90% of leaks are done in under an hour.

Common Mistakes That Make Leaks Worse

- Overtightening slip-joint nuts and crushing the washer.

- Using tape on compression or slip joints, preventing proper sealing.

- Forcing misaligned pipes to meet—add an extension or adjustable trap instead.

- Reusing old flattened washers after a disassembly.

- Skipping the top-down check and blaming the trap when the basket strainer is the culprit.

When to Call a Pro

Get help if shutoff valves won’t close, you see signs of hidden water damage in the cabinet walls or floor, the drain stub-out in the wall is loose, or any part of the drain is galvanized steel that’s rotting back into the wall. Also call if you smell sewer gas after reassembly; that means the trap isn’t sealing, or a vent issue exists beyond the cabinet.

Final Check Before You Close the Cabinet

Run hot and cold for two minutes, fill the sink and release a full-bowl drain, then inspect every joint with a dry tissue. If it stays bone dry for five minutes, you’re good. Wipe any drips you created during testing so new moisture later stands out. A quick recheck tomorrow catches slow weepers before they damage the cabinet.