If you are asking how do i replace a kitchen sink faucet, the short answer is: shut off water, relieve pressure, disconnect supply lines, remove the old faucet and plate, clean the deck, set the new gasket or putty, drop in the faucet, tighten the mounting hardware, connect supply lines and sprayer hose, then turn water on and check for leaks. Below is the deeper how and the why so you do it once and it works.

Tools, materials, and what they do

Basin wrench: reaches the hard-to-access mounting nuts behind the sink bowls.

Adjustable wrench and channel-lock pliers: for supply line and hose connections.

Bucket and towels: to catch residual water when you disconnect lines.

Plumber putty or silicone: seals the base if the faucet lacks a gasket or if the sink texture demands it.

PTFE tape: for threaded male connections if specified; most braided supply lines use rubber washers instead.

New braided supply lines: often wiser to replace than reuse to avoid slow leaks and weak washers.

Prep that prevents leaks

Clear the cabinet and put a towel and bucket under the shutoff valves. Turn off both hot and cold stops. Open the faucet to relieve pressure. If the stops do not close fully or seep, that is a red flag: replace the stops now or shut water off at the main before proceeding. A stuck or seeping stop is the top cause of surprise drips later.

Snap a quick photo of the undersink layout including the sprayer or pull-down hose path and the hole pattern. This avoids rework when reconnecting hoses or ordering the wrong faucet.

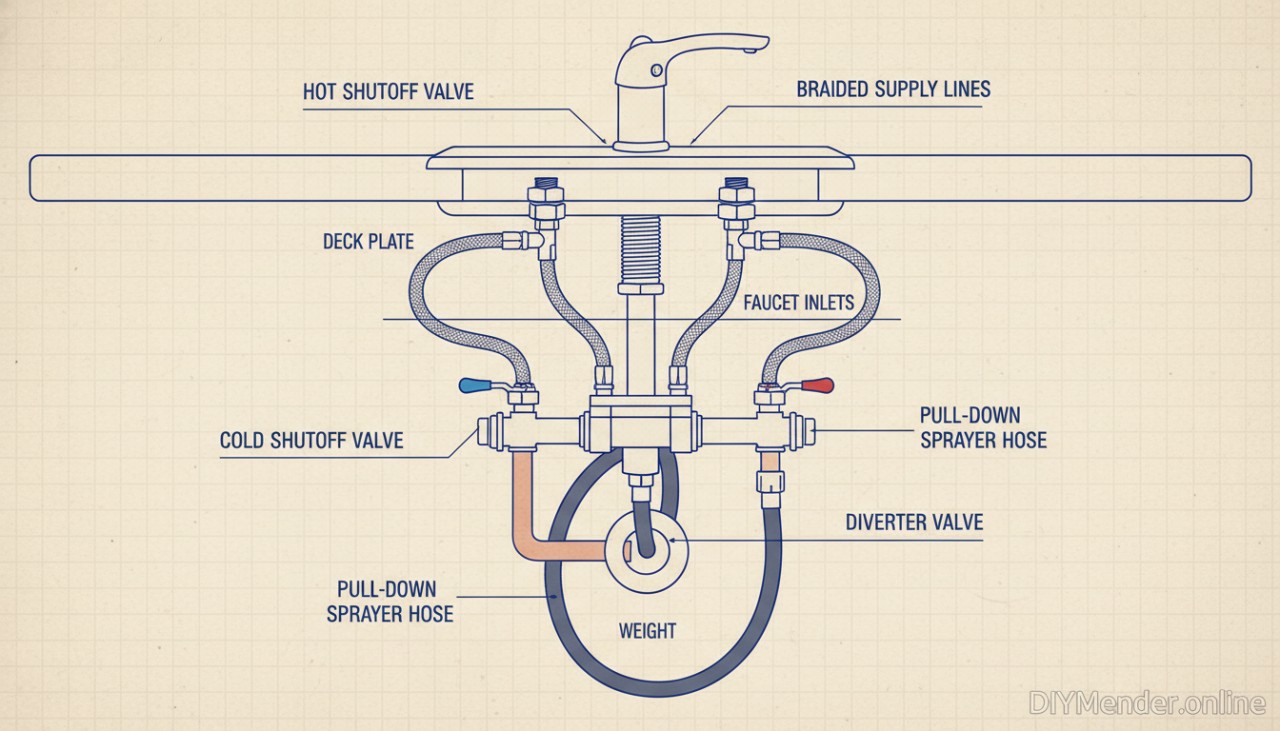

See the diagram below for the undersink layout and the typical path of supply and sprayer hoses.

Remove the old faucet

Disconnect the supply lines at the shutoff valves. Hold the valve body with one wrench while loosening the line nut with another so you do not twist the valve off the pipe.

If there is a side sprayer or pull-down hose, disconnect it at the quick-connect or threaded union. Press the tabs on quick-connect fittings; do not pry, or you will damage the clip.

Use the basin wrench to loosen the faucet mounting nuts. Corrosion is common; a shot of penetrating oil and a few minutes of patience save time. If the nuts are fused to the studs, a nut splitter or mini-hacksaw may be necessary.

Lift the faucet and any deck plate off. Scrape old plumber putty or silicone with a plastic scraper. Clean to bare, dry metal or porcelain; sealants stick to clean, not to old gunk.

Install the new faucet correctly

Match the hole count: a single-hole faucet can cover 3 holes with a deck plate, but a true 3-hole faucet cannot fit a single hole without adding a plate or changing sinks. Always test-fit before sealing.

Gasket or putty: If the faucet includes a rubber gasket, prefer that. On textured stone or when no gasket is supplied, use a thin ring of plumber putty around the base or plate. Putty works because it never fully hardens, maintaining a watertight seal as the sink expands and contracts. On porous stone, use silicone to avoid oil staining from putty.

Drop in and align: Set the faucet, check it is square to the back wall, and thread the shanks and hoses through. Hand-start the mounting nuts to avoid cross-threading.

Tighten evenly: Using the basin wrench, tighten the mounting nuts alternately until the base is snug and the faucet does not rotate. Over-tightening can warp a stainless sink or crack porcelain; snug plus a quarter-turn is usually right.

Connect supply lines: Hot to left, cold to right. Hand-tighten first, then a small wrench nudge. If your lines have cone washers, skip PTFE tape; it can cause overtightening and leaks. Use tape only on tapered threaded pipe fittings where specified.

Sprayer or pull-down hose: Route with a smooth loop and attach the weight at the marked zone. Friction points cause poor retraction; keep the path clear of cleaners and bins.

Why things leak or feel wrong

Drip at supply connections: Usually a crushed or mis-seated washer. Loosen, re-seat, and retighten gently. PTFE tape does not fix a bad washer.

Base puddle: Missing gasket or too little sealant, or flexing of a thin sink. Add a reinforcing plate or use a thicker deck plate if the sink flexes.

Weak flow: Aerator debris or debris in the cartridges from disturbed sediment. Flush lines before final aerator install: remove the aerator, open valves, and run water for 30 seconds per side.

Clunking pull-down hose: Weight hitting plumbing or cabinet. Re-route and ensure the weight can hang freely.

Common mistakes I see and how to avoid them

Reusing old supply lines. The rubber hardens and splits later. Replace with braided stainless lines sized to reach without tension.

Cranking on shutoff valves that already seep. Replace them; otherwise, the slow seep corrodes everything under the sink.

Skipping the deck cleanup. Sealant on grime equals leaks. Clean and dry is faster than chasing a microleak later.

Overtightening plastic nuts or sprayer connectors. Plastic deforms; stop when it seats.

Ignoring hole patterns. A 4-inch centerset plate will not cover 8-inch widespread holes cleanly.

Edge cases and limits

Granite or quartz tops: Use silicone, not oil-based putty, and avoid overtightening to prevent cracks.

Undermount sinks with tight backsplashes: Clearance is minimal. A compact basin wrench or removing the sink trap for arm room helps.

Wall-mounted faucets: Different job entirely; shutoff and rough-in are inside the wall. Call a pro unless you are confident with plumbing inside walls.

Rusted galvanized or immovable stops: Shut water at the main and replace stops with compression or push-to-connect valves if compatible. Twisting can snap an old stub-out and escalate the job.

Three-hole sink, single-hole faucet: Use the manufacturer deck plate to cover holes or add soap dispenser or filtered water tap to fill extras.

Test and finish

Before aerator goes on, open both shutoffs, then run water to purge air and debris. Check every joint with a dry tissue; water shows immediately.

Operate hot, cold, and the sprayer. Look for base weeping, supply drips, and hose leaks under load.

Wipe away squeezed-out putty or silicone. Put the aerator back on after the flush.

Time, cost, and when to call a pro

Typical DIY time is 45 to 90 minutes if shutoffs cooperate. Tools plus new braided lines run modestly, and most homeowner-grade faucets install without special parts. Call a pro if your shutoffs will not close, if the mounting hardware is fused and you lack cutting tools, if you have wall-mounted faucets, or if there is active corrosion on the stub-outs. That is where a simple faucet swap can become a pipe repair.

Follow the steps above and you will replace your kitchen faucet once, without chasing leaks later, and with smooth sprayer action and solid flow.