If you’ve ever stood in a showroom tapping different basins and wondering why they sound, weigh, and age so differently, you’re not alone. People ask, “what is a kitchen sink made of?” because the material drives day-to-day use, noise, stain resistance, and even how hard the install will be. Here’s how the common sink materials are actually constructed and why they behave the way they do in real kitchens.

What Is a Kitchen Sink Made Of?

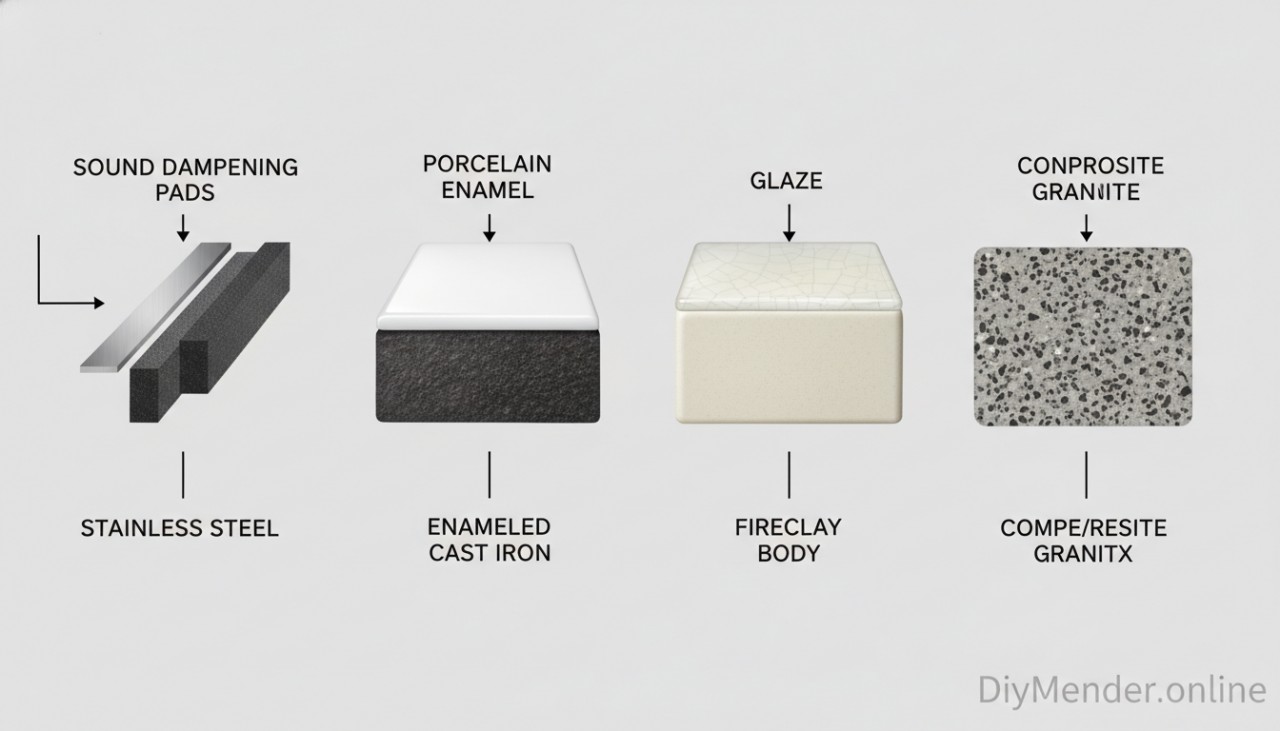

Most kitchen sinks are made from one of a few families of materials: stainless steel, porcelain-enameled cast iron or steel, fireclay, engineered composites (granite or quartz with resin), solid surface (acrylic-based), metals like copper or brass, or heavier slabs like natural stone and concrete. Each starts with a base material and, in many cases, a coating or resin that changes how it looks and wears.

Here’s how each type is built, how it tends to fail, and the details that actually matter once it’s in your home.

Stainless Steel

Formed from a single sheet of stainless and pressed into shape, then trimmed and finished. Better sinks use thicker metal and add underbody pads or spray for sound-deadening.

- What matters: Gauge. Lower number = thicker metal. 16–18 gauge resists dents and rings less under a garbage disposal than 20–22 gauge.

- Why they fail: Thin bowls can oil-can (pop) and dent around the drain or corners. Cheap models lack insulation, so they’re loud and sweat (condensation) in humid basements.

- Care reality: They don’t “rust,” but iron particles from steel wool or cast iron pans can leave orange tea-stains. A nylon scrub and Bar Keepers Friend usually clear it.

Porcelain-Enameled Cast Iron (and Steel)

Heavy cast iron or pressed steel coated with vitreous porcelain enamel and fired. The enamel is glass: glossy, hard, and color-stable.

- What matters: Thickness of the enamel and the base. Cast iron is quieter and feels solid; enameled steel is lighter and a bit louder.

- Why they fail: Enamel chips if a pot kisses an edge; the chip exposes dark metal that can rust. Once chipped, it’s cosmetic forever—touch-up paint blends but never vanishes.

- Care reality: Avoid dropping cookware and don’t use abrasive scouring on glossy enamel. A rubber grid or roll-up mat saves edges.

Fireclay

A molded clay body, glazed and fired at very high temperatures. Popular for farmhouse aprons because the thick walls and glaze look classic.

- What matters: True fireclay is dense and heavy. Look for consistent wall thickness and a flat rim to seal well against the countertop.

- Why they fail: Micro-crazing (fine lines in glaze) from thermal shock or manufacturing variance; corner cracks if the cabinet or support rail isn’t dead-level.

- Care reality: Tough against stains, but the glossy glaze can scuff from pans; nonabrasive cleaners and a sink grid help.

Composite “Granite” or Quartz

Crushed stone (usually 70–80%) bound with resin and molded. The color runs through the material, so there’s no coating to chip.

- What matters: Resin quality and stone ratio. Dark colors hide stains but show mineral spots; light colors can tint if you soak tomato sauce or tea.

- Why they fail: Prolonged heat (just-off-the-oven pans) can warp or discolor resin; harsh bleach can fade spots. Cheap blends feel plasticky and scratch.

- Care reality: Daily rinse and wipe; remove hard-water film with a mild descaler and recondition with mineral oil to even out sheen.

Solid Surface (Acrylic-Based)

Same family as solid-surface countertops. Acrylic or polyester resin with fillers, cast into a seamless bowl. Often paired with a seamless undermount to the same counter brand.

- What matters: Seam quality with the countertop and repairability.

- Why they fail: Heat deformation and staining in matte finishes; heavy impacts leave white scuffs.

- Care reality: The upside is you can sand and buff out many scratches and stains. Just don’t pour boiling pasta water directly on a dry basin—run the tap first.

Copper (and Occasionally Brass)

Formed from sheet metal and hand- or machine-hammered. Copper develops a living patina that shifts with use, water chemistry, and cleaners.

- What matters: Thickness (gauge) and pure copper versus plated. 14–16 gauge copper feels solid and resists dings better.

- Why they fail: Thin copper dents; acidic cleaners or bleach blotch the patina; leaded solder in very old or decorative sinks can be a concern.

- Care reality: Gentle dish soap only. Expect color changes; that’s the point. If you want a frozen-in-time finish, copper may frustrate you.

Natural Stone and Concrete

Either carved from a slab (soapstone, marble, granite) or cast concrete sealed with a topical or penetrating sealer.

- What matters: Weight and sealing. These are extremely heavy and need robust cabinet support and careful undermount hardware.

- Why they fail: Etching from acids (marble), water-darkening or efflorescence, hairline cracks from insufficient support, and sealer maintenance lapses.

- Care reality: Blot spills, reseal as recommended, and avoid thermal shock (don’t set a screaming-hot pot on a cold, wet basin).

Acrylic Drop-In Sinks

Molded plastic shells that are very light and easy to install in rental or temporary setups.

- What matters: Cost and simplicity.

- Why they fail: Scratch, discolor, and flex under heavy disposals or thick faucets.

- Care reality: Fine for light use; not great with cast iron cookware or heavy daily cooking.

Noise, Weight, and Mounting: Details That Change Daily Use

Two sinks can look alike but feel very different once installed. Stainless with thick gauge and sound pads runs quieter under a disposal. Dense materials (cast iron, fireclay, stone) are naturally quieter but can stress a flimsy cabinet. Undermounts rely on a flat rim, solid support rails or brackets, and correct sealant—skimp here and you’ll get sagging, broken caulk lines, or pooled water at the front edge.

I’ve seen undermounted fireclay crack because a center support was off by 1/8 inch, shifting the load to a corner. I’ve also replaced a thin stainless that “tanged” every time the sprayer hit it; upgrading to 16 gauge with pads cured the noise without changing the countertop.

Common Misconceptions I See

“Stainless always scratches, so it’s bad.” It will scuff, but a uniform brush develops and looks fine. Deep dents, not hairlines, are the real annoyance—choose thicker gauge.

“Enamel is fragile.” The glass layer is very tough to wear, but it chips from sharp impacts. A simple basin grid prevents 90% of chips.

“Composite never stains.” Dark resins hide a lot, but turmeric, tea, and hard water can mark them. Regular rinsing and the right cleaner keep them even.

Quick Material Matching to Real-Life Kitchens

- Heavy cookware user, garbage disposal, and kids: Thick-gauge stainless with pads or cast iron enamel for quiet and durability.

- Farmhouse look, willing to support the weight: Fireclay with a protective grid and careful install.

- Want matte, colored options, moderate heat use: Quality composite granite/quartz and gentle cleaners.

- Love character and patina: Copper, but accept dents and changing color.

- Design-first, custom build with strong cabinets: Stone or concrete, professionally supported and sealed.

When DIY Isn’t the Right Call

If the sink weighs over 80–100 pounds (cast iron, fireclay, stone), plan for extra hands, ledger rails, or professional install. For undermounts, I use mechanical supports (brackets or rails) in addition to adhesive—relying solely on silicone is asking for a call-back.

If your countertop is laminate, most undermounts aren’t compatible without special systems. For stone tops, cutting a larger opening or moving to a farmhouse style means dust control, wet-cutting, and support changes—shop work is safer than onsite guesses.

Bottom Line

What your sink is made of dictates sound, weight, chip resistance, stain behavior, heat tolerance, and how much forgiveness you have during install. Pick the material for how you cook and clean, then choose the build details—gauge, sound-deadening, grid, and proper support—to make it live well in your kitchen.