If you’re wondering what are school bathroom sinks made out of, the short answer is: tough, sanitary materials that can take hits and clean up fast. I’ve specified and repaired plenty of institutional fixtures, and the material choice always comes down to vandal resistance, hygiene, lifecycle cost, and maintenance bandwidth.

What Are School Bathroom Sinks Made Out Of?

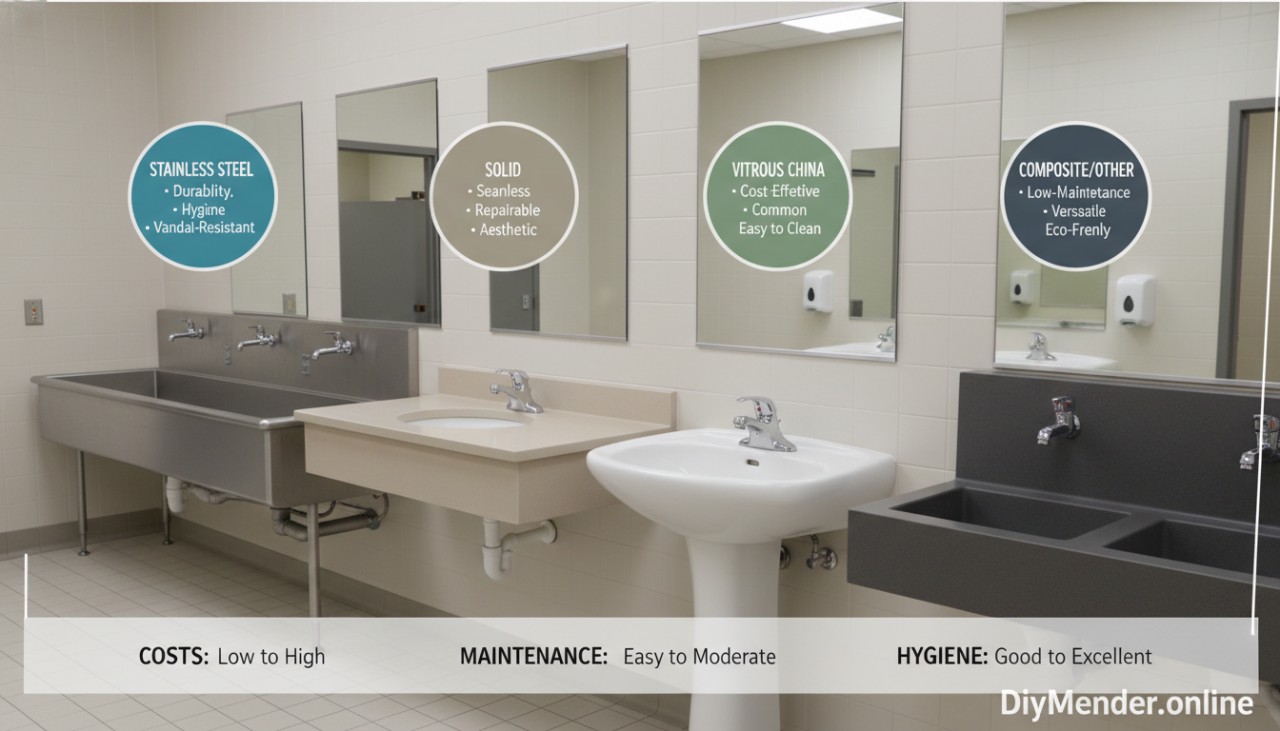

Most schools rely on a handful of proven materials, each chosen to balance durability, safety, and cleaning ease. Here’s how they stack up in real-world use.

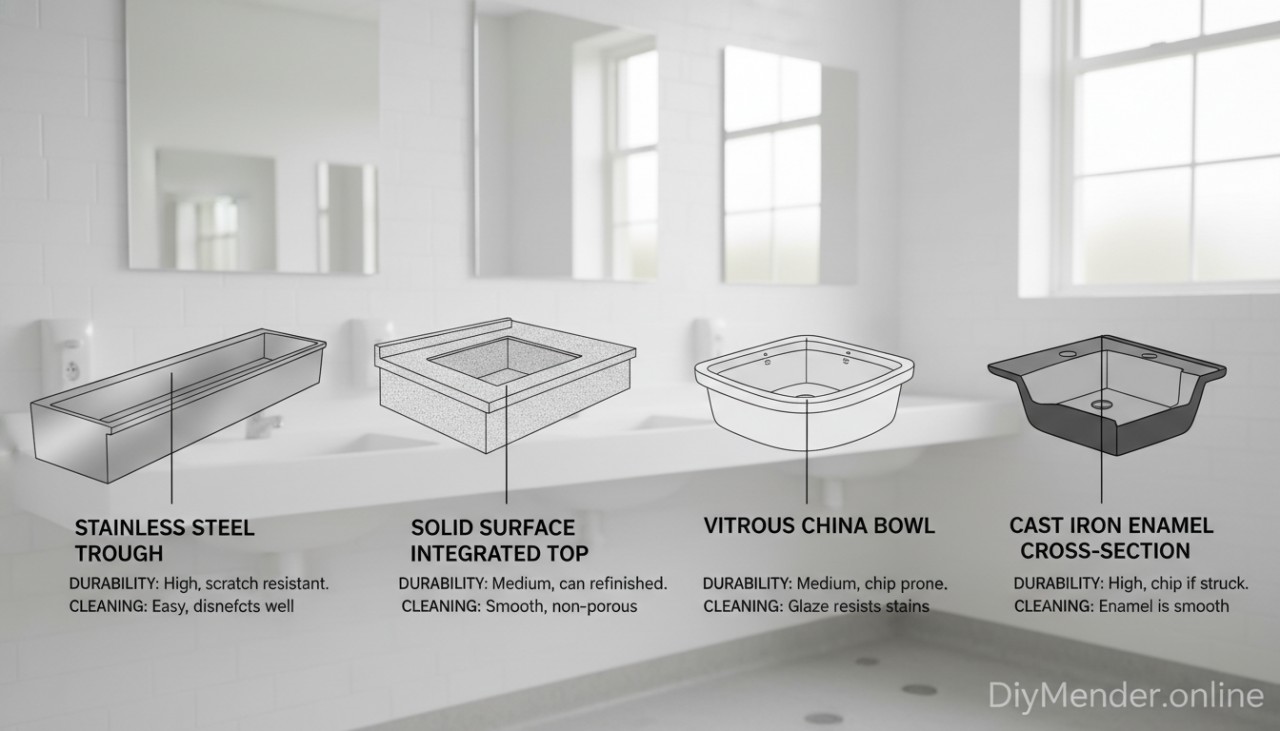

Stainless Steel (Type 304 or 316)

Common in high-traffic or vandal-prone restrooms, stainless steel basins and troughs survive rough treatment. They won’t shatter, they shrug off disinfectants, and welds can be repaired if damaged. The downside is cosmetic: they scratch and show water spots if not wiped. 316 grade is used when chlorine-based cleaners are frequent or in coastal areas due to better corrosion resistance.

Solid Surface (Acrylic/Polyester Composites)

These one-piece counters with integrated bowls work well in modern schools. They look clean, have seamless edges (fewer grime traps), and small chips or burns can be sanded and repaired—huge for extending life. Heat and sharp impacts can scar them, and harsh solvents may dull the finish, so maintenance teams need the right cleaners and pads.

Vitreous China (Porcelain)

Classic, smooth, and highly sanitary, vitreous china wall-hung or drop-in sinks clean beautifully and resist staining. The tradeoff is brittleness—one hard impact with a backpack hook or metal bottle can chip or crack them. In elementary schools with gentler use, they last for decades; in rougher environments, maintenance calls increase.

Cast Iron with Porcelain Enamel

An old workhorse. The heavy iron body takes abuse; the glassy enamel surface cleans easily and resists chemicals. When the enamel chips down to iron, rust appears and spreads under the glaze. Spot repairs are possible but never invisible. These are heavy to install and need solid wall or vanity support.

Engineered Stone and Quartz Composites

Used for integrated counter-and-bowl units in newer builds. They offer good stain resistance and a premium look, while being tougher than many solid surfaces. They still need non-abrasive cleaners, and thermal shock (boiling water then ice) can stress them, though that’s uncommon in schools.

Terrazzo and Epoxy-Resin Troughs

Older schools often have terrazzo troughs—stone chips in cement or epoxy that last ages and handle crowds. Epoxy-resin troughs are lighter and chemical resistant. Both minimize splash and are efficient for groups. Terrazzo needs sealing to prevent staining; epoxy can discolor under UV through windows if not formulated correctly.

Why These Materials Win in Schools

Schools need sinks that: resist impacts and tampering, tolerate harsh disinfectants, drain without pooling, and stay safe (rounded edges, anti-scald mixing). Seamless or integral designs reduce mold risk. Wall carriers and anti-ligature fixtures are common in secondary schools for safety and vandal resistance.

Hardware and Mounting Matter as Much as the Bowl

The sink is only half the story. Commercial carriers, heavy-gauge brackets, tamper-resistant fasteners, and metering or sensor faucets keep the system alive. Traps are often concealed behind access panels to cut tampering. With trough sinks, continuous back-splash guards and correctly sloped decks prevent standing water that breeds mildew.

What You’ll See Most by School Type

Elementary: vitreous china or solid surface with rounded fronts, thermostatic mixing to prevent scalds, and slower-flow aerators to reduce splash.

Middle/High School: stainless or solid surface troughs, concealed carriers, and sensor faucets to cut water waste and vandalism.

Renovations in Older Buildings: cast iron enameled or terrazzo kept if structurally sound; otherwise, replaced with solid surface for easier cleaning and ADA compliance.

Cleaning and Maintenance Realities

Daily disinfecting is hard on finishes. Stainless tolerates bleach and quats but looks better if dried; use microfiber and neutral cleaners for best appearance. Solid surface and engineered stone prefer pH-neutral cleaners; abrasives dull them. Vitreous china handles strong cleaners but chips can’t be truly repaired; replace if cracks reach the drain area. Cast iron enamel needs chip touch-ups fast to stop rust creep.

Cost and Lifespan Considerations

Stainless costs more up front than china but often wins on lifecycle in tough environments. Solid surface sits in the middle: higher initial cost, lower maintenance, and easy cosmetic repair. Terrazzo and epoxy troughs spread plumbing and faucet costs across many users, cutting per-station expense and simplifying cleaning routines.

Home vs. School: Why You Can’t Just “Use the Same Sink”

Home sinks aren’t designed for groups, disinfectant cycles, or tampering. Residential porcelain or composite bowls chip or craze under constant impact and harsh chemicals. If you’re building a home mudroom for team sports crowds, a stainless or solid surface utility sink with a vandal-resistant faucet is a smarter choice than a decorative vanity bowl.

When a Pro Is Necessary

Institutional sinks tie into carriers, ADA clearances, tempered water mixing, and sometimes recirculating systems. If you’re replacing a school sink or trough, bring in a commercial plumber and verify compliance (mounting heights, knee clearance, sensor timing, backflow prevention). Improper installs lead to leaks behind walls or injuries from sharp, unsupported edges.

Quick Material Match Guide

High vandal risk: stainless or epoxy-resin trough.

Clean, modern look with repairable surface: solid surface or engineered stone.

Budget-conscious, lower abuse: vitreous china.

Long-lived legacy kept in place: cast iron enamel or terrazzo if intact.

Edge Cases and Gotchas

Hard water: mineral buildup makes stainless look tired and clogs sensor faucets—use descaling protocols and good aerators. Cold climates: unheated wings can stress solid surfaces and gaskets; choose materials rated for temperature swings. Sunlit restrooms: UV can yellow some resins; specify UV-stable formulations. Aggressive student art projects: solvents can haze plastics—lock down cleaner choices and train staff.

In short, schools choose materials that survive routine abuse, clean quickly, and meet safety codes. Pick the one that matches the building’s reality, not just the catalog photo, and you’ll save years of headaches.