If water is spraying or you’re swapping a faucet, you can’t waste time hunting for instructions. Here’s exactly how to turn off water below kitchen sink, plus what to do when stubborn valves won’t budge and how to avoid breaking anything.

How to turn off water below kitchen sink

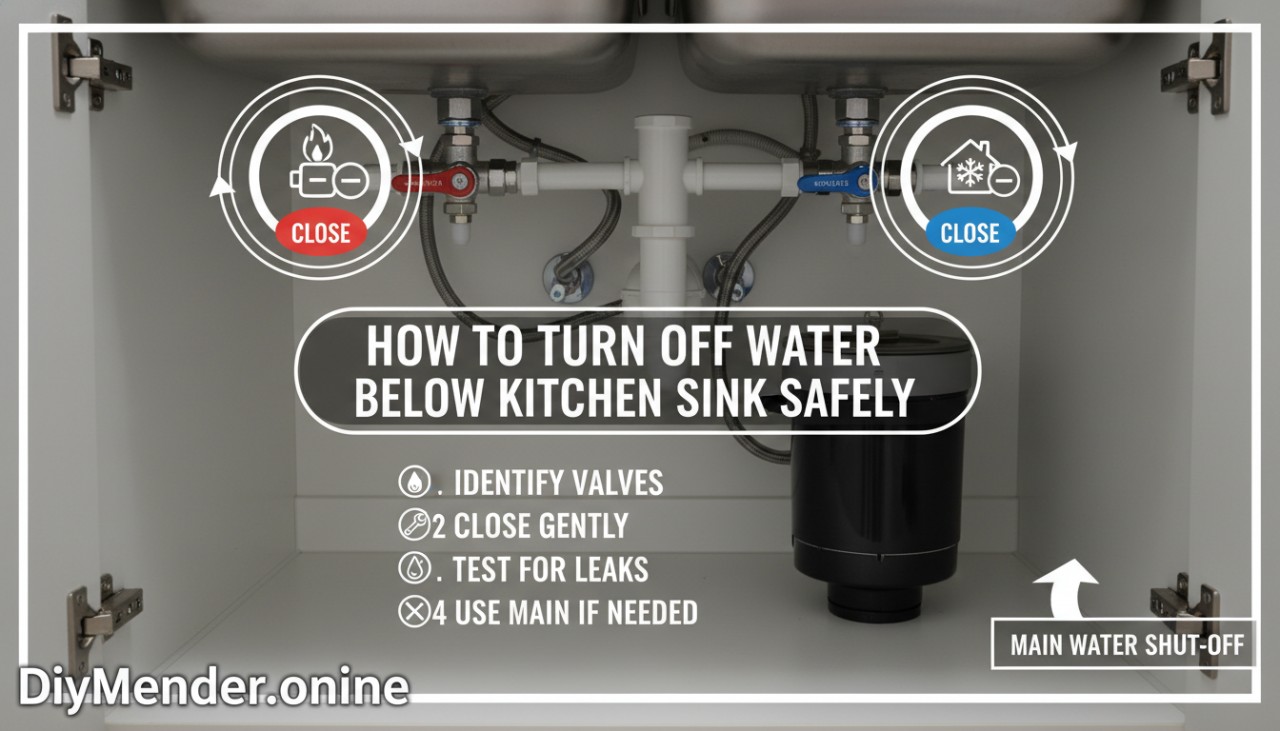

Most sinks have two shut-off valves (angle stops) inside the cabinet at the back: one for cold (usually right side) and one for hot (usually left). You’ll see flexible supply lines running from each valve up to the faucet. Your job is to close those valves safely, confirm water is off, then relieve pressure so you don’t get a surprise later.

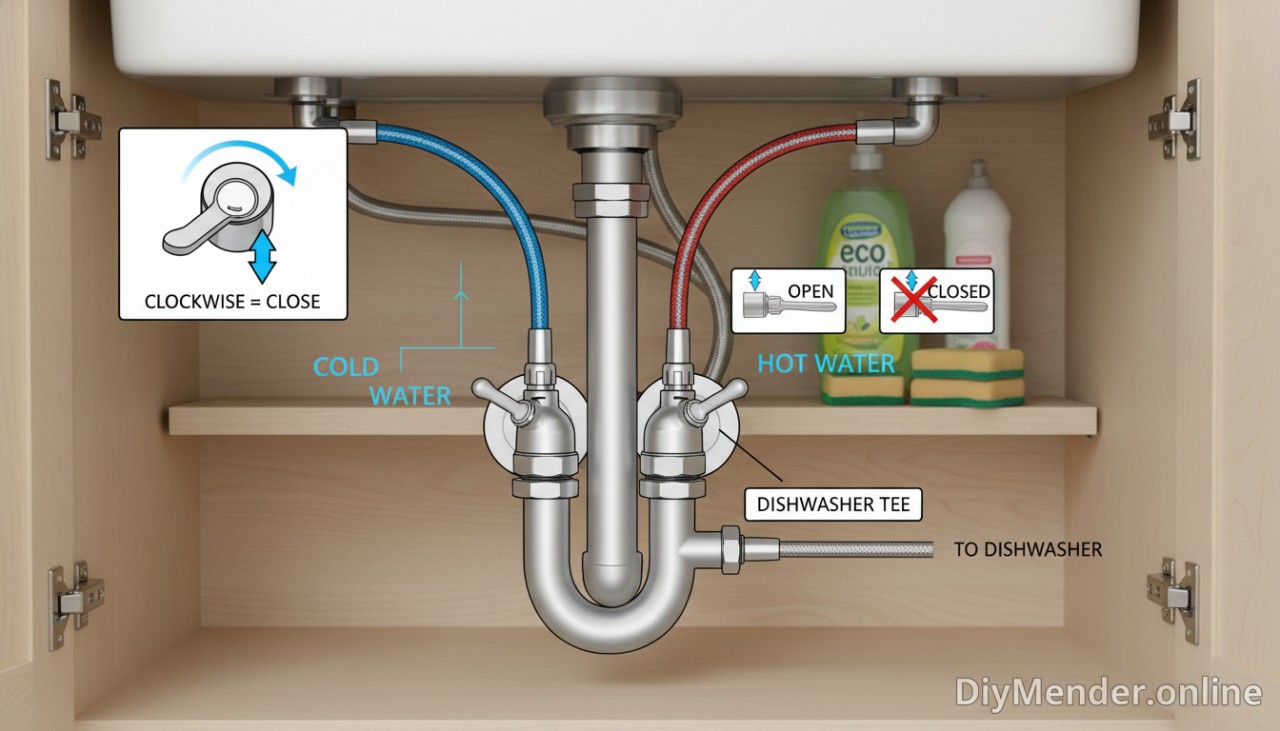

Identify your valve type

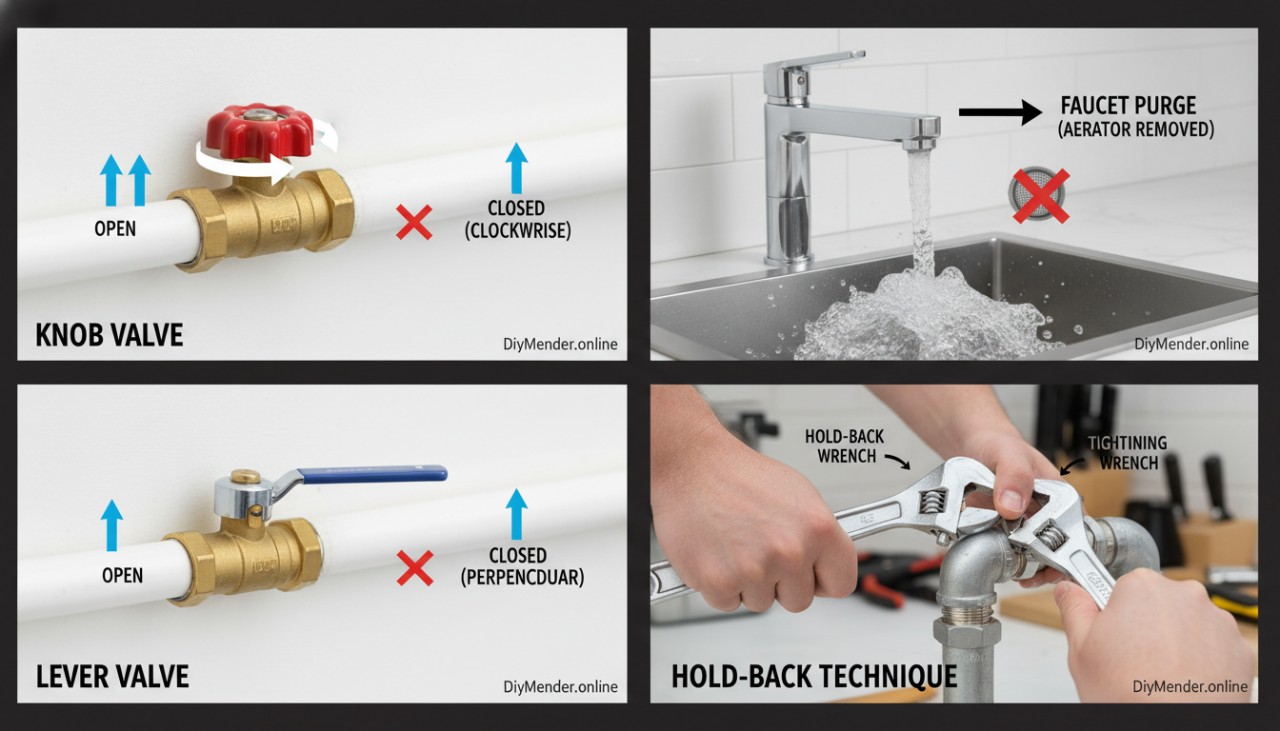

- Quarter-turn ball valve: A small lever handle. Turn the lever 90 degrees so it’s perpendicular to the pipe to close. These usually move smoothly.

- Multi-turn compression valve: Round knob you twist clockwise several turns to close. Older ones can bind, leak at the stem, or not seal fully.

- Integrated appliance tees: Some setups have an extra outlet feeding a dishwasher, filter, or RO system. Make sure the correct branch is closed if you’re working on a specific line.

Tip: Hot and cold labeling isn’t guaranteed. If unsure, trace the line from the faucet tailpieces down to the stops rather than guessing.

Step-by-step: Close the water and verify

- Clear the cabinet so you have room. Put a towel and small bowl under the valves in case they drip.

- Turn off the garbage disposal and dishwasher at their switches so they don’t run dry or surprise you.

- Close the cold valve first. For a knob, turn clockwise until snug—firm, not forced. For a lever, rotate 90 degrees to perpendicular. Repeat for the hot valve.

- Open the faucet handle(s) to relieve pressure. Water should taper to a trickle and stop. If it continues to run, one or both stops didn’t seal—try tightening a touch more.

- Check for seepage at the valve stem (under the knob) and at the compression nut. If the stem weeps after closing, snug the small packing nut a quarter-turn while holding the valve body with a wrench. Don’t over-tighten.

- If you’re disconnecting supply lines, back the faucet handle to the off position first so you’re not spraying residual water. Then loosen the supply nut at the faucet with a wrench and catch a few ounces of water.

When a shut-off valve is stuck

Multi-turn valves that haven’t moved in years can freeze up. What works for me:

- Support the valve body with one wrench while you turn the knob with your hand. Avoid using pliers directly on the knob—stripping it just creates a bigger problem.

- If it resists, don’t force it. Apply a drop of penetrating oil to the stem where it enters the packing nut, wait a few minutes, then try gently working it back and forth.

- If the stem turns but never seats (keeps spinning) or leaks worse, the internal washer or stem is shot. At that point, plan to shut off the house main and replace the stop.

Warning signs you should stop and go to the main shut-off: the valve body twists with the pipe, green crust or heavy corrosion, or the supply line kinks while you’re turning the handle. Any of those can snap something and flood the cabinet.

Can’t find or reach the valves?

Some older or tight installations hide the stops behind trash bins, disposal cords, or back inside deep cabinets. If you truly can’t reach them safely, use the home’s main shut-off:

- Street-side or basement/crawlspace main: Quarter-turn lever or large gate valve near where the water line enters the house. Turn the lever perpendicular to the pipe, or spin a gate valve clockwise until it seats.

- Condo or high-rise: Look for a unit isolation valve in a utility closet. If none is accessible, call building maintenance before proceeding.

After using the main, open a lower-level faucet to relieve pressure, then confirm your kitchen faucet is dry before working.

Special cases: dishwasher, filter, and fridge lines

- Dishwasher: Often shares the hot stop via a small branch valve. Close both the main hot stop and the branch. Run the dishwasher for a second to confirm it won’t fill.

- Under-sink filter/RO: These often have their own tiny quarter-turn valves on tubing. Close the dedicated valve and the cold stop feeding it.

- Fridge ice maker: If fed from under the sink, trace the small copper or braided line back to a saddle valve or tee. These can be unreliable; close it and then verify at the fridge by attempting to dispense water.

Prevent drips and damage while you work

- Hold-back technique: Any time you tighten or loosen supply connections, use one wrench to steady the valve body and a second to turn the nut. This prevents twisting soft copper or PEX stubs in the wall.

- Replace brittle supplies: If braided lines are rusted or more than 10 years old, replace them now. Kinked or swollen lines are accidents waiting to happen.

- Use new washers: If you disconnect a compression supply, check the cone washer. A flattened or cracked washer won’t reseal reliably.

Restarting water without shock

- Close the faucet handles.

- Open the cold valve first, slowly. Listen for any hiss or sudden spray at connections. Then open the hot valve.

- Open the faucet and let it run to purge air. Sputtering is normal for a few seconds. Check below for leaks while it runs.

- If flow is weak afterward, remove the faucet aerator and flush out debris, then reinstall it.

What goes wrong and why

Older multi-turn stops fail because the rubber washer hardens or the stem threads wear. They’ll either never seal or they leak at the packing nut. Quarter-turn ball valves are far more reliable because the seal is a hard ball and seats, but mineral buildup can still make them stiff. Corroded copper stubs can twist if you wrench the valve without supporting it, and plastic supply lines can crack from over-tightening. These are the pitfalls that turn a 5‑minute shutoff into a messy hour.

Upgrades worth doing while you’re there

- Swap to quarter-turn angle stops. They’re easier to operate in an emergency.

- Install separate stops for dishwasher and filters so you can service them independently.

- Use stainless braided supplies of the correct length—no coils or sharp bends.

When to call a pro

Get help if the valve is seized and the pipe flexes, the stop leaks from the body, you have galvanized or heavily corroded piping, or you must shut the building main and aren’t confident restarting. A plumber can replace a stop in minutes with the right tools, and that’s cheaper than repairing a flooded cabinet and damaged flooring.

Quick checklist

- Towels, bowl, flashlight, two adjustable wrenches

- Identify two stops; close cold, then hot

- Verify at faucet; relieve pressure

- Watch for stem leaks; snug packing nut if needed

- If stuck or corroded, use the main shut-off and plan a replacement

- Turn water back on slowly; purge air; check for leaks

Once you’ve done this once, the under-sink layout makes sense, and you’ll be much faster the next time a faucet needs attention or an emergency pops up.