If you want to know how to polish stainless steel sink to a mirror finish, here’s the exact method I use as a hands-on homeowner: level out the factory brushing with uniform fine sanding, step through progressively finer grits to remove each previous scratch pattern, then buff with stainless-specific compounds and seal. Plan 2–4 hours for a typical single-bowl sink. This works because a mirror isn’t about “shine spray”—it’s about turning random, light-scattering scratches into ultra-uniform, ultra-fine scratches that reflect light coherently.

Tools and Materials That Actually Work

- Random orbital sander (ideal) with interface pad, or a patient hand-sanding block

- Wet/dry papers: 600, 800, 1200, 2000, 3000 grit (Micro-Mesh 2400–8000 optional)

- Felt or foam polishing pad (drill or DA sander) and microfiber cloths

- Compounds: cutting (brown Tripoli or similar) and stainless finishing compound (green/white)

- Cleaner: Bar Keepers Friend or a non-chloride stainless cleaner; isopropyl alcohol

- Masking tape, plastic sheeting, nitrile gloves, eye protection

- Lubricant: water with a drop of dish soap in a spray bottle

- Optional protectant: carnauba wax, paint sealant, or ceramic spray (non-abrasive)

Before You Start: Assess the Sink

Not all stainless finishes can or should be mirror polished in place. Brushed and satin 304/316 sinks respond well. PVD-colored sinks (black, bronze, gold) should not be sanded—you’ll remove the coating. Textured, hammered, or patterned stainless won’t go mirror. Deep pits, dents, and creases won’t disappear; chasing them can thin the metal.

Step-by-Step: From Brushed to Mirror

1) Prep and Decontaminate

Mask the countertop, faucet, and backsplash. If possible, remove drain flanges and strainers. Clean the basin thoroughly with Bar Keepers Friend and rinse. Degrease with isopropyl alcohol so abrasives cut consistently. Any leftover grit or scale will create new scratches.

2) Commit to Uniformity

To achieve mirror, you must erase the factory grain across the entire bowl; spot-polishing creates shiny blotches around dull fields. You’re aiming for a uniformly fine, directional scratch pattern at each stage, then a finer one, and so on.

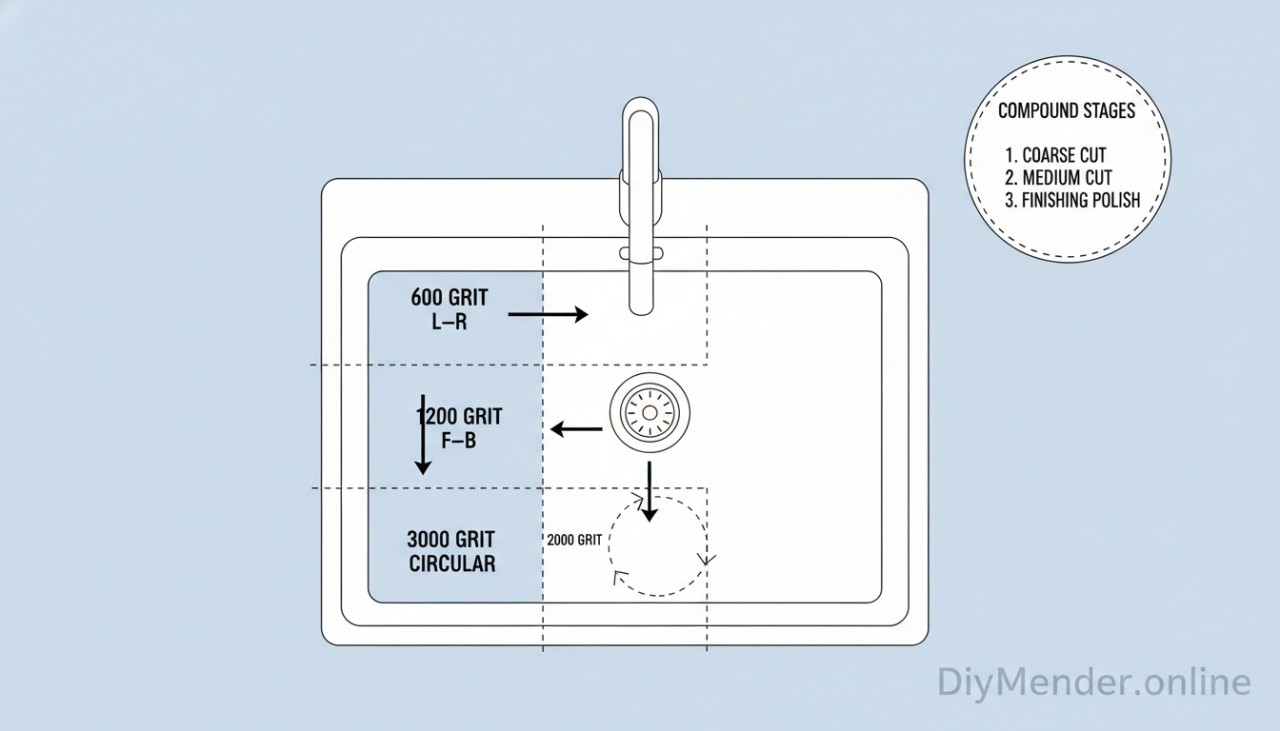

3) Leveling Pass: 600 Grit

Lightly wet-sand with 600 grit. Work in small sections, moderate pressure, long strokes. Keep the pad flat to avoid scallops. Choose one direction (say, left–right). Your goal: a consistent 600-grit finish across the whole basin—no visible remnants of the original brush lines.

4) Refinement Passes: 800 → 1200 → 2000 → 3000

After each grit: rinse thoroughly and wipe with a clean microfiber to avoid cross-contamination. At each new grit, sand in a perpendicular direction to the previous pass (e.g., front–back). This makes it obvious when the previous scratches are fully removed. Use water with a drop of dish soap for lubrication and cooling.

By 2000 grit you should see a uniform sheen with no deep lines. At 3000, the surface will begin to look glossy even before compound.

5) Compounding: Cut Then Finish

Attach a felt or firm foam pad to a variable-speed drill or DA polisher. Spread a small amount of cutting compound (Tripoli or a stainless cutting compound). Run low-to-medium speed (about 1200–1800 RPM equivalent), light pressure, slow overlapping passes. Keep the pad moving to avoid heat tint (rainbowing). Wipe residue and inspect.

Switch to a finishing compound (green stainless or white) on a clean pad. Repeat with even lighter pressure. You’re now smoothing micro-scratches below the eye’s threshold. Finish by wiping with isopropyl alcohol to remove oils that can fake gloss.

6) Seal the Finish

Apply a non-abrasive wax, paint sealant, or ceramic spray. This doesn’t make it more “mirror,” but it slows water spotting and fingerprinting by reducing surface energy, so the sink stays mirror longer.

Why This Works (and Why Shortcuts Don’t)

Stainless dulls because of random scratches and embedded mineral film—both scatter light. Each sanding step must fully replace the previous scratch pattern with a finer, more uniform one. If you skip grits, you’ll have deeper scratches that compounds can’t remove efficiently; you’ll chase haze forever. Compounds polish by cutting the peaks of micro-scratches; they can’t flatten valleys left by coarse paper you didn’t remove.

Common Mistakes That Ruin the Finish

- Skipping grit stages or not fully removing previous scratches

- Cross-contaminating: reusing a cloth or pad from a coarser step

- Using steel wool: it sheds carbon steel that causes rust stains later

- Overheating with a grinder: causes rainbow heat tint and can warp thin bowls

- Dry sanding entirely: higher risk of clogging and deep random scratches

- Bleach or chloride cleaners afterward: can pit stainless and dull the finish

- Attacking a single scratch only: creates shiny patches surrounded by haze

Limits, Edge Cases, and Reality Checks

- Thin-gauge sinks (builder grade) can “oil-can” if you bear down; use lighter pressure and a block.

- Deep pits or gouges: stop at safe flatness. Chasing them risks thinning the sheet.

- Integrated drain grooves and corners: hand-sand with small blocks; power tools can dish edges.

- PVD-colored or coated sinks: do not sand; use non-abrasive polish only.

- Heavily brushed finishes: expect extra time at 600/800 to fully erase the grain.

Troubleshooting Haze, Swirls, and Tints

- Gray haze after finishing: likely compound residue. Wipe with IPA, then a very light pass with finishing compound on a clean pad.

- Visible straight scratches: you didn’t fully remove the previous grit. Drop back one grit, finish that stage perfectly, then move up again.

- Rainbow discoloration: heat. Light 2000–3000 wet-sand to break it, then re-finish at lower speed with less pressure.

Care to Keep It Mirror

- Rinse and wipe dry after use to prevent mineral spots

- Mild cleanser only; avoid abrasives and chlorides

- Monthly: quick pass with a non-abrasive stainless polish or spray sealant

- Use microfiber; avoid rough sponges

Quick Run-Through

Clean and mask. Sand 600 (uniform), 800, 1200, 2000, 3000 (alternate directions; rinse between). Compound with cutting, then finishing. IPA wipe. Seal. That’s the reliable path to a true mirror stainless sink at home.